Introduction

Week 1 - Simple edge finishes

Week 2 - French seams

Week 3 - Bound seams

Week 4 - Flat fell seams

Week 5 - Taped (stabilised) seams

Week 6 - Overlocked seams

Week 7 - Bulky seams

Week 8 - Curves and corners

Introduction

For the final week of my work on my seam sampler, I decided to try some decorative seams: finishes that can be used to pretty-up the outside of a project. I had great fun trialling top stitching, binding and piping.

Top stitched seams

Top stitching is a visible line of stitching found on the finished side of the seam. This simple,decorative stitch line gives a nice smart finish to the seam.

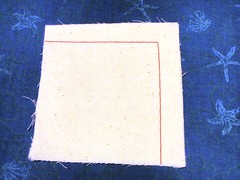

To start, I tried out single top stitching using some denim. First I sewed a plain seam and then press it to one side.

Next I threaded my machine up with a nice contrasting red thread (put your sunglasses on!).

Ideally top stitch is done with a proper top stitching - or button hole twist - thread. This is a heavier weight thread that really stands out. I used Gutterman branded thread. You need only thread the spool - the bobbin can take normal weight thread.

From the right side of the fabric, I then sewed a single (relatively!) straight line parallel to the seam edge. See how well the top stitch thread stands out?

For a fancier effect you can do double top stitching - two parallel lines.

You can sew the lines separately, but the easiest way to create a double row is to use a twin needle.

If you haven't tried one of these before they are great fun. They come in a variety of types and gauges (e.g. stretch, universal, jean), as well as having varying distances between the needles.

Aside from the twin needle (shown below) you do need a second spool pin on your machine. Initially I had to hunt around on my Janome, working out what to do. Some machines have a fixed second spool pin, but on my machine the vertical second pin is a little attachment.

Once you have set up your second spool pin, you pop both reels on the machine (I

Note: It is possible for the two threads to get tangled and break during sewing. It can get UGLY! To minimise the chance of this happening, pass the thread down separate sides of the little tension disc near the top of the machine, when you are threading. Try also to sit the reels on the spool pin so one winds clockwise and the other, anti-clockwise.

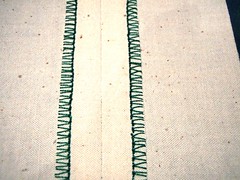

Finally, as you sew you will see two beautiful evenly spaced lines of stitching appear. On the reverse size of the stitching, you will see a sort of zig-zag stitch that passes between the two lines. This is because you have only one thread available from the bottom (bobbin).

Bound seam

The seam is created by binding matching the wrong sides of the fabric together and then enclosing the seam in bias binding. I have tried this on a couple of bags. It works nicely where the seam doesn't need to be opened out flat and gives a clean finish to the inside of the seam.

For this finish you need a length of purchased or handmade double-fold bias binding.

In the example below, I matched the wrong sides of the denim fabric together.

Next I open one side of the bias binding out and matched its edge with the edge of the seam allowance. I then pinned it in place.

The next step was stitch all the way along the fold line on the bias binding.

Once this was done, I carefully turn the free edge of the binding over, to enclose the the whole seam edge. Again, I pinned the binding in place.

Finally I "stitched in the ditch" - that is the little dip where the denim fabric and the binding met. This caught in the binding on the reverse side.

Et voila! A nice neat bias bound seam.

Piped seam

Piping is a tube of bias-cut, decorative fabric that you sew into the seam. There are two sorts: flat (just the fabric tube) and corded (where the tube wraps around a piece of cord). For my sampler, I decided to try making corded piping. You can purchase different-sized piping cord from haberdasheries.

To begin, I cut a strip of fabric on the bias. If you have a long seam and need lots of piping, you will almost certainly need to join the fabric strips end-to-end. Its a very similar process to making bias binding - see here for some photographs demonstrating how to attach the ends.

The width of the strip needs to be great enough to enclose the cord and leave a 1.5cm [⅝"] seam allowance.

Next, I enclosed a piece of cord and matched the raw edges of the fabric strip. I then pinned it to hold the cord in place.

Then, I attached a zipper foot to my machine and positioned it to the left of the needle. A zipper foot allows you to sew close to the cord. (There are also special piping presser feet you can buy for different machines).

A word of warning ... in my excitement/naivety I sewed a little bit too close in to the cord! See how close the needle is? Whew - I sewed up that cord within an inch of its life!!

The wise sewer would leave a wee gap, so that one additional row of stitching can be added between this stitch line and the cord, when sewing the actual seam later.

Finally I sandwiched the piping between the fabric, with the right sides of the denim together. The cord faced away from the seam allowance. Then I stitched the seam.

After turning the seam right-side out, the pretty, rounded piping is visible.

Channel seam

This is a very cute seam - certainly something a little bit different. I chanced upon it this week while reading through a reference book. Its classified as a top-stitched seam, but has an interesting twist.

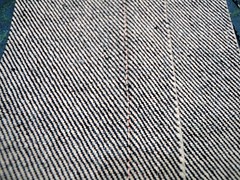

To begin, I machine basted a plain seam (using nice long stitches), then pressed the seam allowance open.

Next I cut a strip of fabric the width of the seam allowance and length of the seam. Matching the right side of the strip with the wrong side of of the seam, I pinned the strip in place. You can choose a matching or a contrasting fabric.

Then I flipped the fabric to the right side and top stitched through all the thicknesses, along both sides of the seam. In the picture below, you can see that I have already sewed down the right-hand side.

And finally, I carefully remove the large stitches from the machine basting, using my seam ripper. This opens up the "channel".

Here is the finished channel seam.

Peek-a-boo!

Conclusion

I will definitely use all these decorative finishes again. They are all quite straight forward, though I would like a little more practice with piping, to make sure I get the stitching in just the right place. The channel seam was a definite favourite, so now I am on the look-out for the right project to use it with.

Do you have other decorative seam finishes that you like using?

Next week: This is the conclusion of the seam-along. I've had great fun putting my sampler together - I hope its been useful to you too. I am on a roll now, so next week I will be starting a hem sampler. Stay tuned for details of the types of machine and hand sewn hems that I will look at. If you would like to hem-along with me, you are most welcome! Update: Hem-related articles can be found over here.